The Mill Complex at Montana Tunnels will allow ESRI to process ores from its mines internally and is a regional asset, making it a key corporate asset.

The Mill Complex is capable of processing 16,000 tons of ore per day through its crushing, grinding, flotation and filtration equipment.

The benfication process at the Mill Complex consists of:

- Crushing: Crush ore grade material from the mine to between five and seven inches in size.

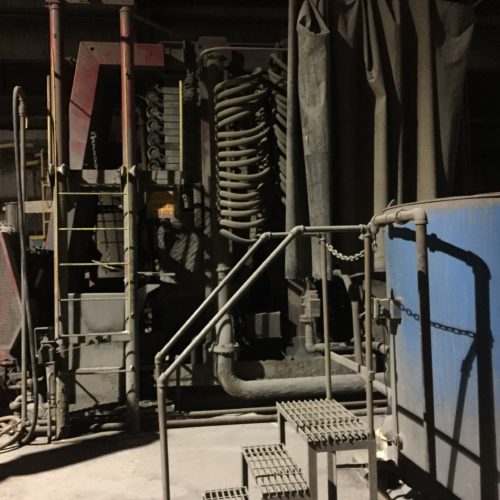

- Grinding: Feed coarse ore stockpile onto conveyor belts and deliver to a grinding mill where it is mixed with water; five inch steel balls grind the ore to create a coarse slurry.

- Flotation and Filtration: The flotation circuit is made up of a series of large tanks, or cells, with each cell containing an agitator and air blower.

- Concentration: Two concentrates are produced from the ore – a lead concentrate and zinc concentrate, with the gold and silver found mostly in the lead concentrate.